Product Description

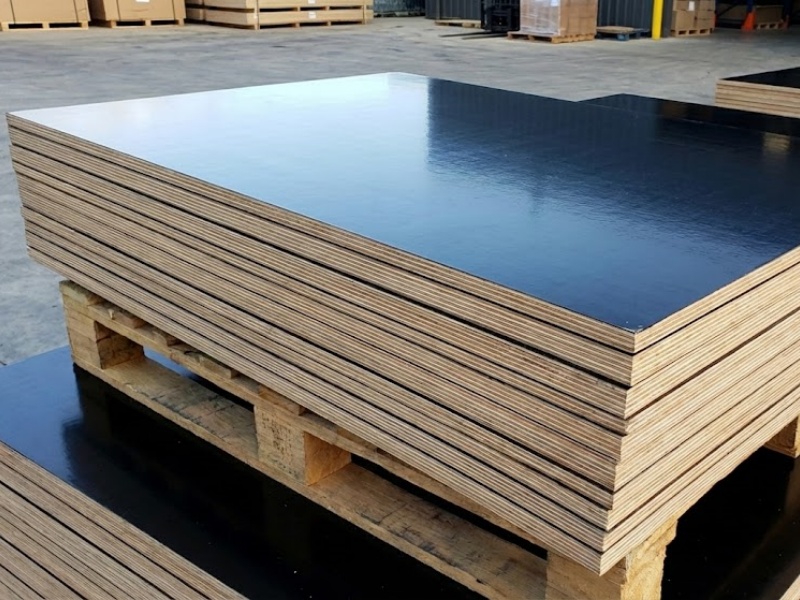

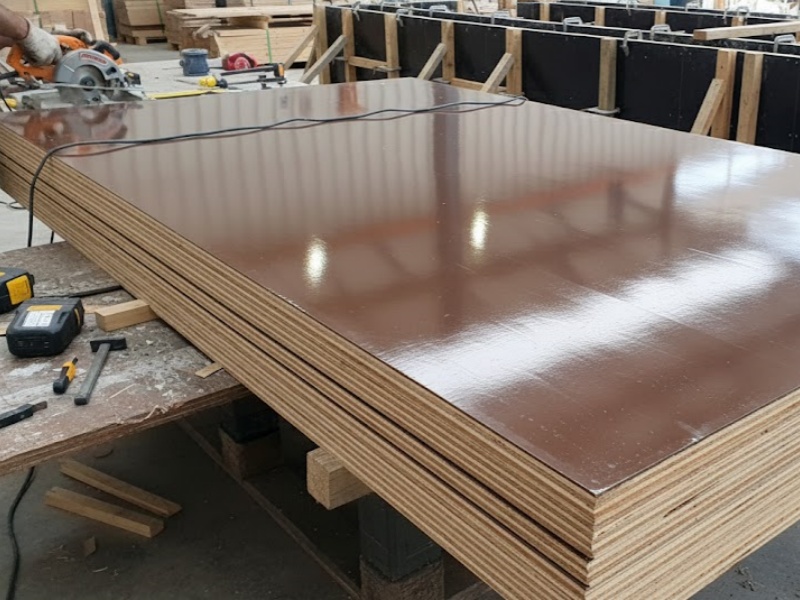

Plastic Film Faced Plywood is a premium construction-grade panel laminated with a protective plastic film on both faces. This structure significantly enhances water resistance, abrasion resistance, and overall durability, making it ideal for concrete formwork and heavy-duty outdoor use.

The plastic-coated surface allows easy demolding, leaving concrete surfaces smooth and reducing the need for secondary polishing. Its high-density, multi-layer core provides excellent load-bearing strength, dimensional stability, and consistent performance under pressure.

This plywood is widely applied in:

-

Concrete formwork systems

-

Building & construction engineering

-

Bridges, tunnels, and foundation structures

-

High-strength flooring and scaffolding platforms

-

Industrial packaging and moisture-proof structures

With strong bonding quality and sealed edges, Plastic Film Faced Plywood performs reliably even in humid environments. Available with glue types such as WBP Phenolic, Melamine, E0, and E1, it meets international standards for durability and environmental compliance.

Product Models & Specifications

|

Model |

Size (mm) |

Thickness (mm) |

Core Material |

Film Color |

Glue Type |

|

PFF-1224-BLK |

1220 × 2440 |

9 / 12 / 15 / 18 |

Poplar / Hardwood |

Black |

WBP / Melamine |

|

PFF-1224-RED |

1220 × 2440 |

12 / 15 / 18 |

Poplar / Birch |

Red |

WBP / E1 |

|

PFF-1250-BLK |

1250 × 2500 |

12 / 18 / 21 |

Mixed Hardwood |

Black |

WBP Phenolic |

|

PFF-Custom |

Custom size |

9–30 mm |

Custom core |

Black / Brown / Custom |

WBP / MR / E0 / E1 |

Product Applications

Plastic Film Faced Plywood is widely used across major construction and industrial projects thanks to its strength, moisture resistance, and smooth surface finish.

Construction & Formwork

-

Concrete formwork systems

-

Wall, slab, and column molds

-

Bridges, tunnels, and civil engineering projects

Industrial Use

Flooring & Scaffolding

-

Temporary flooring

-

Scaffold platforms

Outdoor Structures

Designed for demanding environments, Plastic Film Faced Plywood offers excellent reusability, clean concrete finishing, and long service life, helping contractors reduce material waste and overall project cost.

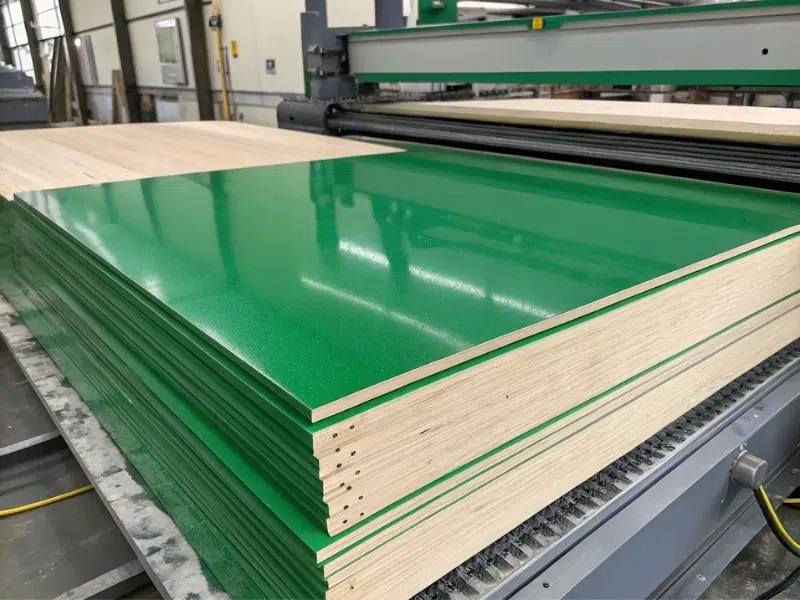

Factory Show

FAQs

Q1. What core materials are available?

Poplar, birch, pine, mixed hardwood, or custom options.

Q2. How many times can the plywood be reused?

Typically 8–15 cycles, depending on handling and project conditions.

Q3. What glue types can be selected?

WBP phenolic, melamine, MR, E0, E1.

Q4. Can you supply custom sizes or film colors?

Yes, both size and film color can be customized based on project requirements.

Share your thoughts

Showing

6

of

0

reviews