Product Description

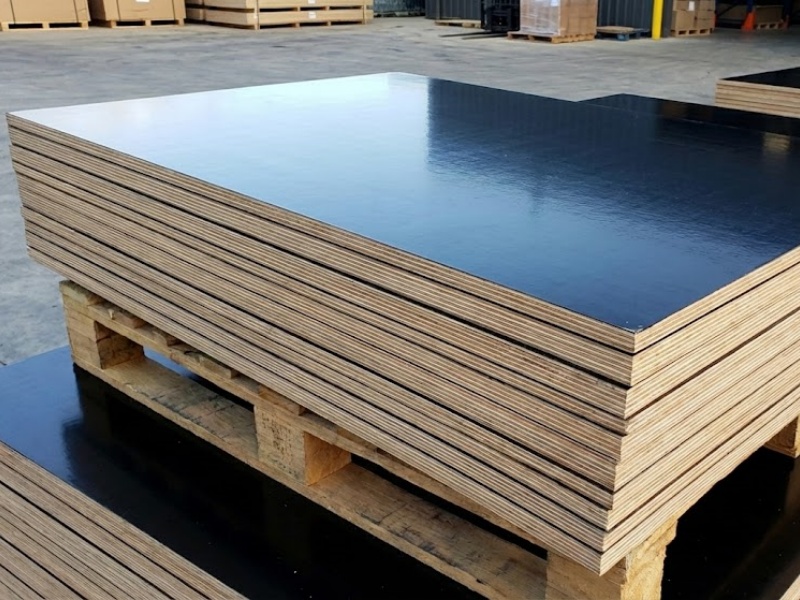

Melamine Faced Plywood is created by hot-pressing a melamine film onto a stable plywood base, producing a decorative panel with both outstanding appearance and high performance. The melamine coating forms a tough, smooth, and waterproof surface that is far more scratch-resistant and durable than traditional laminates or veneer finishing.

This versatile panel is widely used in:

-

Modern home and office furniture production

-

Wardrobes, cabinets, shelves & built-in storage systems

-

Interior wall cladding and decorative partitions

-

CNC machining for customized furniture components

-

Commercial fixtures, shopfitting & display systems

The plywood core options include Poplar, Hardwood, Birch, or Combi structures, giving customers flexibility in balancing cost, strength, and application needs. With a wide selection of surface designs—wood textures, solid colors, marble patterns, or custom prints—Melamine Faced Plywood provides excellent aesthetic value for both residential and commercial spaces.

Glue types include WBP, Melamine, E0, E1, and E2, offering different levels of moisture resistance and environmental compliance. This ensures the panels meet global standards for safe indoor use and long-term durability.

Product Models & Specifications

|

Model |

Size (mm) |

Thickness (mm) |

Surface Finish |

Core Material |

Glue Type |

|

MFP-1224-WG |

1220 × 2440 |

9 / 12 / 15 / 18 |

Woodgrain |

Poplar / Combi |

Melamine / E1 |

|

MFP-1224-MT |

1220 × 2440 |

6 / 9 / 12 / 18 |

Matte / Glossy |

Hardwood / Birch |

WBP / E0 / E1 |

|

MFP-1250-DW |

1250 × 2500 |

12 / 15 / 18 |

Double-faced |

Poplar |

E1 / E2 |

|

MFP-Custom |

Custom size |

3–30 mm |

Custom color & texture |

Custom core |

WBP / MR / E0 / E1 / E2 |

Product Applications

Melamine Faced Plywood is widely used in modern interiors and commercial environments, thanks to its excellent decorative performance and mechanical stability.

Furniture Manufacturing

-

Cabinets, wardrobes, drawers

-

Office desks, hotel furniture, shelves

Interior Decoration

-

Wall panels, ceiling panels

-

Decorative partitions, door surfaces

Commercial & Retail Fixtures

CNC Machining & Customized Panels

Industrial & Packaging (Decorative Grade)

With its strong plywood core and high-quality melamine coating, this panel is suitable for both functional furniture and high-traffic decorative areas, offering excellent surface durability and a long service life.

Factory Show

FAQs

Q1. What surface textures and colors are available?

We offer woodgrain, solid color, matte, high-gloss, marble, and custom design options.

Q2. Do you support custom sizes and thicknesses?

Yes, customized specifications are available according to project requirements.

Q3. What glue types can be selected?

E0, E1, E2, Melamine, WBP, or MR depending on moisture and environmental requirements.

Q4. What is the typical delivery time?

Generally 15–25 days depending on order quantity and specifications.

Share your thoughts

Showing

6

of

0

reviews