Product Description

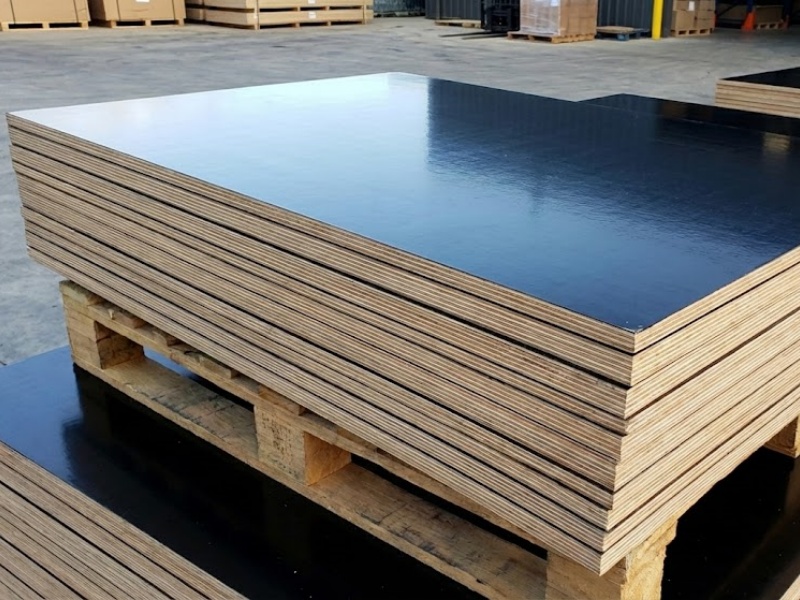

Marine Plywood is a premium-grade plywood specifically engineered for applications exposed to water, humidity, and demanding environmental conditions. Manufactured with carefully selected hardwood veneers and bonded with waterproof phenolic adhesives, it offers outstanding resistance to delamination and structural failure.

Unlike standard plywood, marine plywood features a dense, uniform core with minimal voids, ensuring excellent load-bearing performance and long-term dimensional stability. This makes it suitable for both structural and decorative uses in wet or outdoor environments.

Marine Plywood is widely used in:

1. Boat building and marine interiors

2. Docking systems, piers, and ship decks

3. Exterior construction and outdoor furniture

4. Bathroom, kitchen, and wet-area installations

Available grades include BS1088, BS6566, and custom marine specifications, with surface options such as sanded, film-faced, or coated finishes. Thicknesses and sizes can be customized to meet specific project requirements.

Product Models & Specifications

|

Model |

Size (mm) |

Thickness (mm) |

Veneer Type |

Glue Type |

Standard |

|

MP-1224-HW |

1220 × 2440 |

6 / 9 / 12 / 18 |

Hardwood |

WBP Phenolic |

BS1088 |

|

MP-1250-MR |

1250 × 2500 |

9 / 12 / 15 / 18 |

Mixed Hardwood |

WBP Phenolic |

BS6566 |

|

MP-1525-EX |

1525 × 1525 |

12 / 15 / 18 |

Hardwood |

WBP Phenolic |

Marine Grade |

|

MP-Custom |

Custom size |

6–30 mm |

Custom veneer |

WBP Phenolic |

Custom |

Product Applications

Marine Plywood is widely used in marine, construction, and industrial sectors due to its outstanding water resistance and structural integrity.

-

Marine & Boat Building: Hull structures and decks, Cabin interiors and bulkheads

-

Outdoor & Exterior Construction: Outdoor furniture and structures, Cladding, roofing, and formwork

-

Wet Area Installations: Bathrooms and kitchens, Laundry rooms and pool surroundings

-

Industrial & Heavy-Duty Use: Industrial flooring, Export packaging and crates

With its exceptional waterproof performance and robust construction, Marine Plywood is the ideal choice for projects requiring maximum durability in challenging environments.

Factory Show

FAQs

Q1.What makes marine plywood different from regular plywood?

Marine plywood uses waterproof glue and higher-quality veneers with fewer core gaps.

Q2. Is marine plywood completely waterproof?

It is highly water-resistant and boil-proof but should be properly sealed for long-term submersion.

Q3. Do you offer certified marine plywood?

Yes, BS1088 and BS6566 standards are available.

Q4. What is the typical delivery time?

15–25 days depending on order size and specifications.

Share your thoughts

Showing

6

of

0

reviews