Product Description

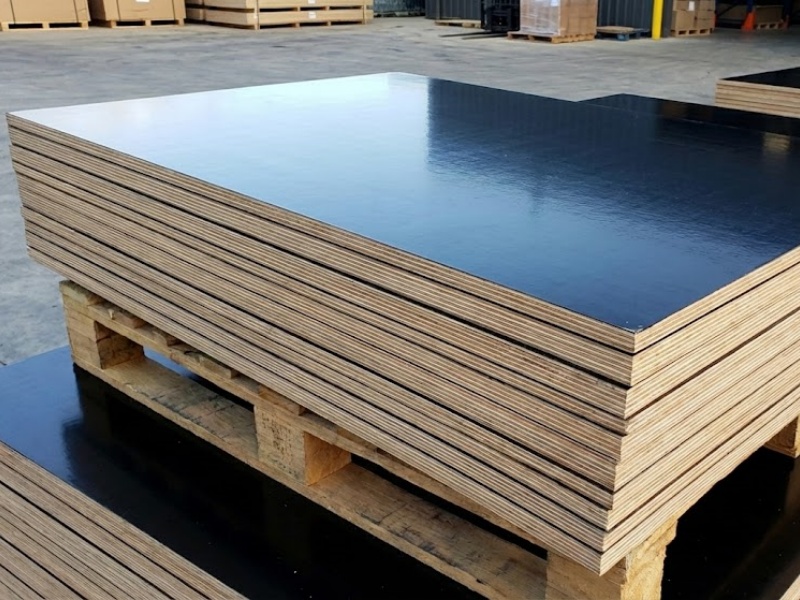

Full Birch Plywood is manufactured using 100% birch veneers for both the face/back and the core, making it one of the strongest, most stable, and most visually appealing plywood options in the woodworking industry.

This premium-grade plywood features a multi-layer birch construction, providing excellent strength, dimensional stability, and superior screw-holding capacity.

It is widely used in:

1. High-end furniture and cabinetry.

2. Interior decoration and architectural applications.

3. CNC machining, laser cutting, and precision woodwork.

4. Vehicle flooring, crates, packaging, and industrial use.

Thanks to its uniform birch core, smooth surface, and tight grain, Full Birch Plywood offers exceptional machining performance and a clean, attractive appearance. Available in multiple veneer grades such as B/BB, BB/BB, BB/CP, and CP/CP, it provides flexible options for projects requiring different surface qualities.

Full Birch Plywood supports various glue types including WBP Phenolic, Melamine, E0, and E1 adhesives. This ensures excellent bonding strength, moisture resistance, and compliance with global environmental standards.

Product Models & Specifications

|

Model |

Size (mm) |

Thickness (mm) |

Veneer Grade |

Glue Type |

|

FBP-1224-BB |

1220 × 2440 |

9 / 12 / 15 / 18 |

BB/BB |

WBP / E1 |

|

FBP-1250-BB |

1250 × 2500 |

6 / 9 / 12 / 18 |

B/BB |

WBP / E0 / E1 |

|

FBP-1525-CP |

1525 × 1525 |

9 / 12 / 15 / 21 |

BB/CP |

Melamine / E1 |

|

FBP-Custom |

Custom size |

3–30 mm |

Custom grade |

WBP / MR / E0 / E1 / E2 |

Product Applications

Full Birch Plywood is widely used across multiple industries thanks to its excellent strength, stability, and clean surface finish. Below are the most common application areas:

-

High-end furniture manufacturing: tables, chairs, cabinets, wardrobes, drawers, office desks.

-

Interior decoration & architectural use: wall panels, ceilings, partitions, door panels, built-in furniture.

-

CNC machining & laser cutting: precision components, craftwork, speaker boxes, DIY projects.

-

Industrial & packaging structures: crates, industrial boxes, reinforced transport packaging.

-

Vehicle & marine applications: flooring panels, trailer interiors, ship interiors, container flooring.

-

Shopfitting & commercial fixtures: display racks, shelves, exhibition stands, retail cabinets.

With its 100% birch veneer construction, this plywood delivers excellent mechanical performance and high aesthetic value, making it suitable for both visible decorative surfaces and heavy-duty structural uses.

Factory Show

FAQs

Q1. What veneer grades are available?

Common grades include B/BB, BB/BB, BB/CP, CP/CP depending on required surface quality.

Q2. Do you support custom sizes?

Yes. Custom sizes, thicknesses, and glue types are available according to project needs.

Q3. What glue types can be selected?

WBP Phenolic, Melamine, E0, E1, E2 adhesives depending on application and environmental requirements.

Q4. What is the typical delivery time?

Generally 15–25 days depending on quantity, grade, and special customization requirements.

Share your thoughts

Showing

6

of

0

reviews